How Japanese Sake Is Made

Despite being called a rice “wine”, sake has more in common with beer as it is brewed through a double fermentation process. Making quality sake involves 4 key ingredients Rice, water, kōji and yeast.

Age-old records written reveal that pasteurization and the process of adding ingredients to the main fermentation mash in three stages were established practices since the late 15th century.

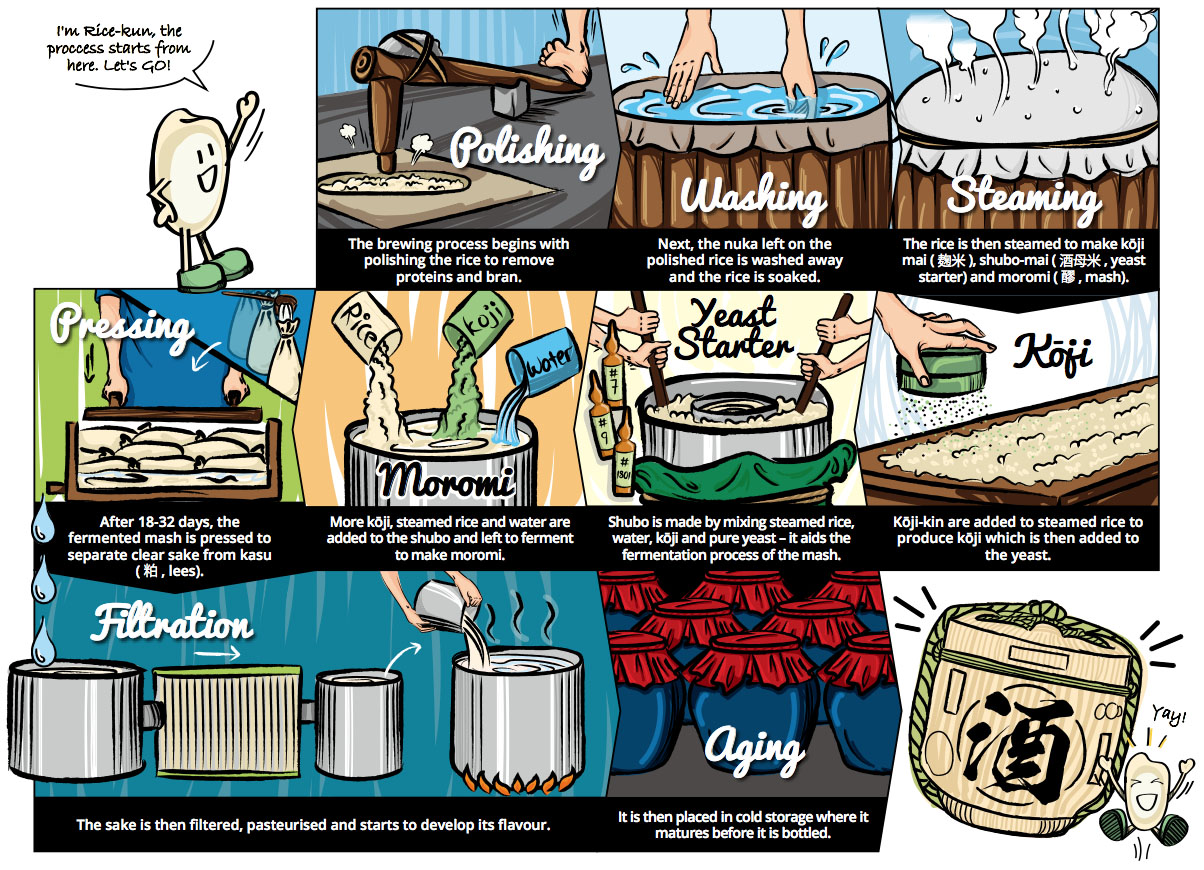

How To Make Sake Step 1: Polishing

The brewing process begins with polishing the rice. It is called “milling,” and there are various machines to help in the process. This step in the sake brewing process removes proteins and bran from the rice that can affect the flavor.

How To Make Sake Step 2: Washing

Next, the nuka, or bran, left on the polished rice is washed away. Then the rice is that will be used for sake is soaked in the water. It remains there until the rice absorbs 30% of its weight in water.

How To Make Sake Step 3: Steaming

After absorbing enough water, the rice is then steamed to make koji-mai ( 麹米 ), shubo-mai ( 酒母米 , yeast starter) and moromi ( 醪 , mash).

Steaming the rice takes about one hour. The steaming process is used because it produces less moist and sticky white rice. This is ideal for the sake making process. Then the rice is left to form fungi spores (koji-kin).

How To Make Sake Step 4: Koji

Enzymes are needed for the brewing process. To break down the rice for sake, this comes from a beneficial kind of mold that forms on the koji. Koji-kin is added to steamed rice to produce koji which is then added to the yeast.

The fungi growing on the koji are most active at about 36°C. However, activity stops if the temperature gets above 45°C. For this reason, the temperature and humidity are carefully controlled during this process.

How To Make Sake Step 5: Yeast Starter

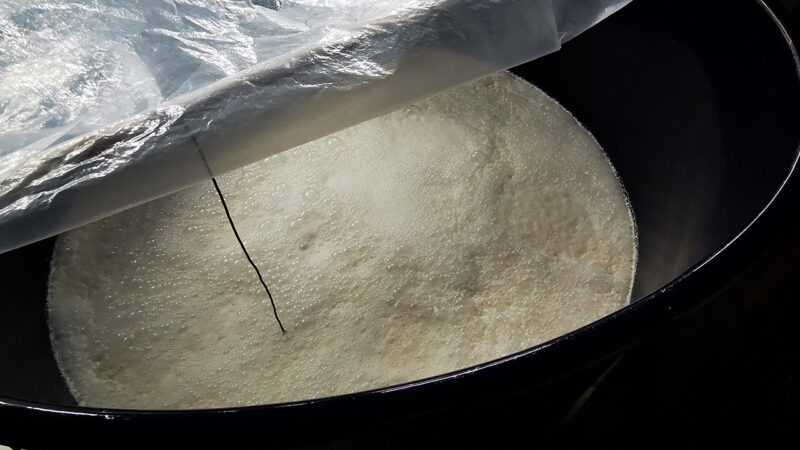

Shubo is made by mixing steamed rice, water, koji and pure yeast. The yeast aids in the fermentation process of the mash.

The shubo mash is kept around a range of 8°–18°C during the fermentation process. About 3 to 4 weeks is needed for the sake mash to ferment enough to produce an alcohol content of about 17%–20%.

How To Make Sake Step 6: Moroni

More koji, steamed rice and water are added to the shubo, which translates to “mother of sake” because of its importance in the sake brewing process.

The shubo is then left to ferment to make the sake moromi (main mash). The enzymes in the koji continue their work breaking down the rice and producing sugars.

How To Make Sake Step 7: Pressing

After 18-32 days, the fermented mash forms from koji-mai, shubo-mai, and moromi. To separate clear sake from kasu ( 粕 , lees), the mash is pressed. This process can be accomplished by filtering the mix through a cloth bag and applying pressure. It is similar to a beer mash filter press.

The leftover cake-like sake residue can also be eaten raw or used in ingredients for other things like shochu or pickled vegetables. It is called sakekasu, and it also contains some alcohol.

How To Make Sake Step 8: Filtration

After pressing, some impurities may remain, so the sake goes through another filtration process. When left to sit for a long enough time at a low temperature, particles settle at the bottom, leaving a clear liquid on top.

Once the sedimentation has finished, the sake is filtered. Then the sake is pasteurized through a heating and cooling process. However, the pasteurization diminishes the sake’s aroma and flavor. From this point, the sake needs to be aged to develop its flavor.

How To Make Sake Step 9: Aging

For aging, the sake is placed in cold storage where it matures before being bottled. The length of the aging process depends on the sake and the brewer. Typically it is left to age for 6 months to a year.

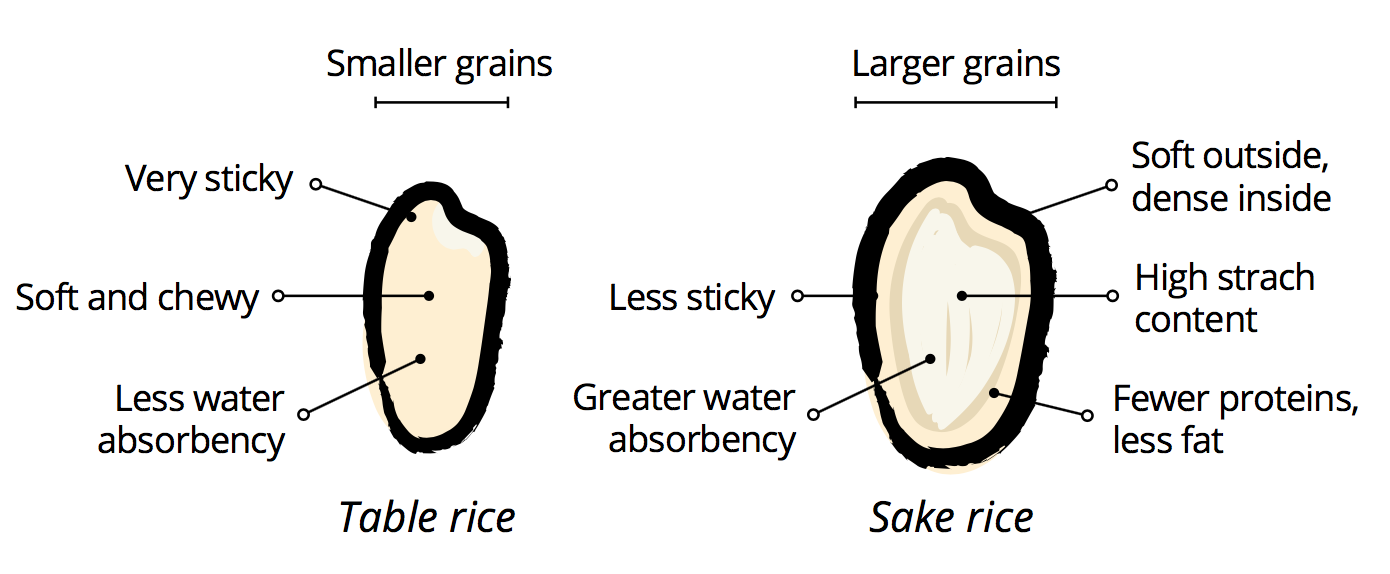

What kind of rice is used for sake?

There are about nine basic kinds of special rice used to make sake. Each of them produces a unique flavor. The king of these sake rice breeds is Yamada Nishiki Rice which gives a fragrant, well-blended, soft flavor. The best grains are grown in Hyogo and Toyama. To produce aromatic sake, rice needs to be polished between 50% to 70%. The more polished the rice, the more delicate it becomes, and the higher the grade of sake it produces.

What kind of water is used for making sake?

Water makes up almost 80% of sake and helps develop its one-of- a-kind taste. Breweries often source their water from nearby springs, mountain runoffs, springs, etc. The water is either kōsui ( 硬水 , hard water) or nansui ( 軟水 , soft water) and they can affect the sort of flavor profile that the sake will take on.

Areas of Japan that have access to plenty of fresh water and natural springs tend to produce the best sake. For that reason, Niigata Prefecture is one of the best regions to produce sake, and Niigata Prefecture is also famous for delicious rice.

How yeast and koji affect the flavor of sake

Yeast has a big influence on how a sake will taste and smell. There is a wide variety of strains, but the most common ones are #7,#9 and #1801. #7 is commonly used in complex sake like Junmai and Honjozo for its subtler, earthier rice aroma while #9 and #1801 are popular for their floral and fruity flavor and fragrance.

20% of rice sake used for brewing is turned into a mold called kōji-kin. Kōji-kin converts the starch in rice into sugar through the process of fermentation. This affects the depth of umami flavor in sake.

0

0